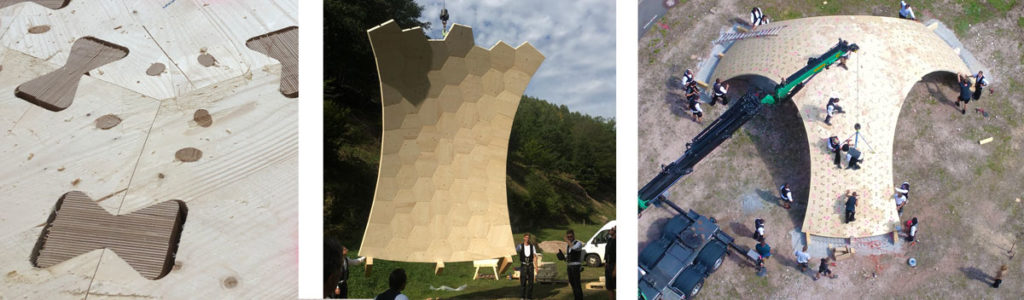

05.09.2019, Kaiserslautern: Can we use digital technology to make high-tech structures from waste material? The production of modern cross-laminated timber (CLT) walls creates a large amount of offcuts for windows and doors. These cutouts are of a high, certified quality and valuable building material, but too small for regular building applications. The Recycleshell uses digital technology to turn these small elements into a high-performance, column-free roof structures, that can be quickly and precisely assembled on site thanks to an innovative rapid-assembly concept using hardwood connectors instead of metal.

Video on LinkedIn

TV Documentation: DTC Recycleshell on SWR Television (in German)

Article in mikado Holzbaumagazin 11/2019 (in German)

Interview with DBZ Deutsche BauZeitschrift 11/2019 “Holz” (in German)

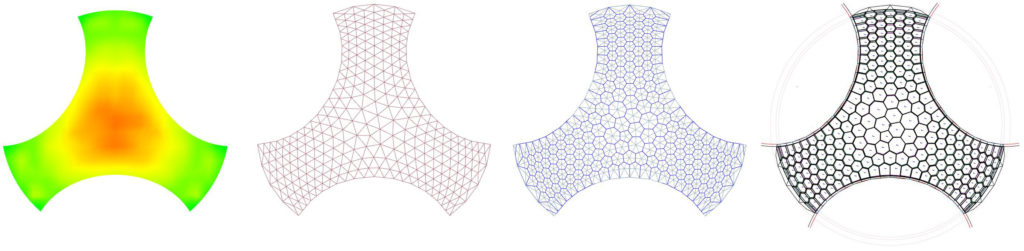

It is inspired by the way nature designs structures: Material is expensive, geometry is cheap. The optimised shell shape, which loads the large number of joints predominantly in compression, is approximated with planar facets made from flat CLT plates.

On the 5th of September, a first recycleshell demonstrator was presented to the public in the Diemerstein Valley near Kaiserslautern. It is also the first project on the University of Kaiserslauterns new “timber construction research campus”. Speeches were given by the University President Prof. Dr. Helmut Schmidt, State Secretary Dr. Thomas Griese, County Council Chairman Theo Wieder, Mayor Eckhard Vogel and Jun. Prof. Dr. Christopher Robeller.

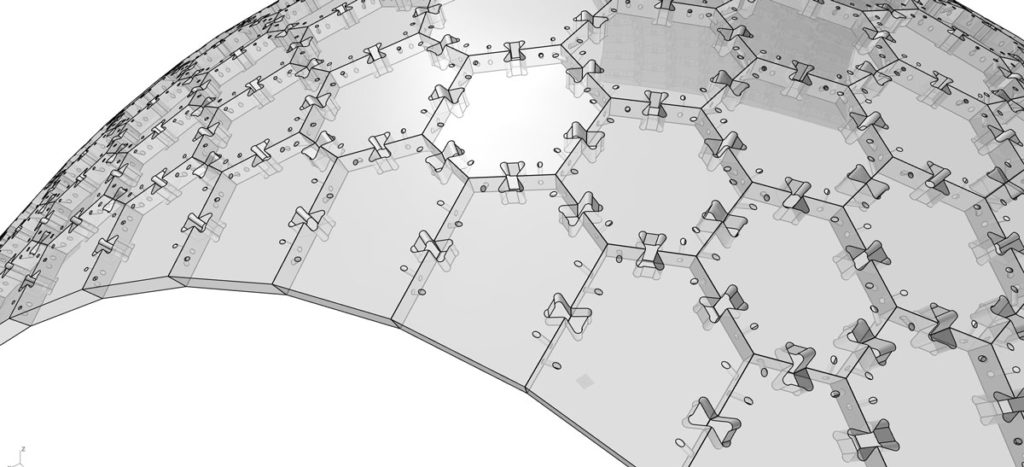

The DTC recycleshell demonstrates an innovative construction system, that can be produced from the CLT cut offs (waste material), which result from window and door cutouts in large amounts. Furthermore, the system is assembled entirely with wooden connectors, a combination of beech wedge connectors and beech dowels – completely without metal screws or bolts. The form fitting joints also act as assembly guides, no substructure was needed for the rapid and precise assembly of the structure.

The demonstrator consists of 230 planar plate elements, its optimised shell form is essential for the construction system, since it loads the joints between the elements predominantly in compression. The element geometries and the direct output of the CNC production data has been designed and generated using a software developed by DTC.

The production data was calculated so that the components could be manufactured fully automatically, with millimeter accuracy and cost-efficiency using state-of-the-art CNC technology of our project partner CLTech GmbH. The assembly is simple, fast and precise, as with LEGO, with the help of special X-Fix beech wood connectors, which were combined with wood dowels. The construction works entirely without metal connectors between the plates.

The material-saving lightweight construction project at the interface of architecture, civil engineering, production engineering and computer science shows new ways of building, thanks to Building Information Modeling BIM and a completely digital process chain.

The 230 individually shaped panel elements and over one thousand individually calculated wood-wood connectors can only be automated by algorithms. For the first time, form-fitting fasteners made of beech wood are used in a free-form tensile structure, which enable a particularly simple, fast and precise construction.

Thanks to our competent and committed supporters from the authorities, industry, university and the town community of Frankenstein, we were able to realise a first demonstrator roof with this new construction technique in the Diemerstein valley near Villa Denis. It vividly illustrates the interesting and architecturally enriching potential of digital design and production processes – using renewable resources and recycled materials.

In a final step, the curved shell structure was covered by a green roof. Both special plants and a special installation system were used for this challenging application, together with our project partners Optigrün and Koch Landschaftsbau, who have particular experience with special green roofs.

Scientific Development:

– Digital Timber Construction DTC, Jun. Prof. Dr. Christopher Robeller

Funding:

– Ministerium für Umwelt MUEEF / Holzbaucluster Rheinland-Pfalz

– CLTech GmbH Kaiserslautern

Production and Assembly:

– CLTech GmbH, Kaiserslautern

– Meisterschule Zimmererhandwerk MHK Kaiserslautern

Structural Engineering:

– Pirmin Jung Deutschland GmbH, Sinzig

Supported by:

– X-Fix, Sepp Schilcher

– Gemeinde Frankenstein

– Kreisverwaltung Kaiserslautern

– Hans Hundegger Maschinenbau AG

– Bezirksverband Rheinland-Pfalz

– Optigrün GmbH

– Koch Landschaftsbau

We would particularly like to thank for their support:

Werner Theis, Hannsjörg Pohlmeyer, Eckhard Vogel, Jürgen Gottschall, Tobias Götz, Sepp Schilcher, Karl-Ludwig Kusche, Marc Derichsweiler, Johann Brill, Ralf Lenhardt, Tobias Frank, Eva Saalfrank, Sebastian Dienst, Niklas von Haaren, Yang Liu, Dirk Schmitt, Karl Jung, Theo Wieder, Christopher Dandrade, Manuel Stürminger, Wolfgang Pritschet, Ingemar Kirchler, Marc Niewöhner, Stefan Lorenz, Kurt Sendldorfer, Bianca Neumann, Sabine Stenzel, Dr Anette Mechel, Peter Spitzley, Dr. Thomas Löber, Dr. Jens Brauneck, Doris Simon